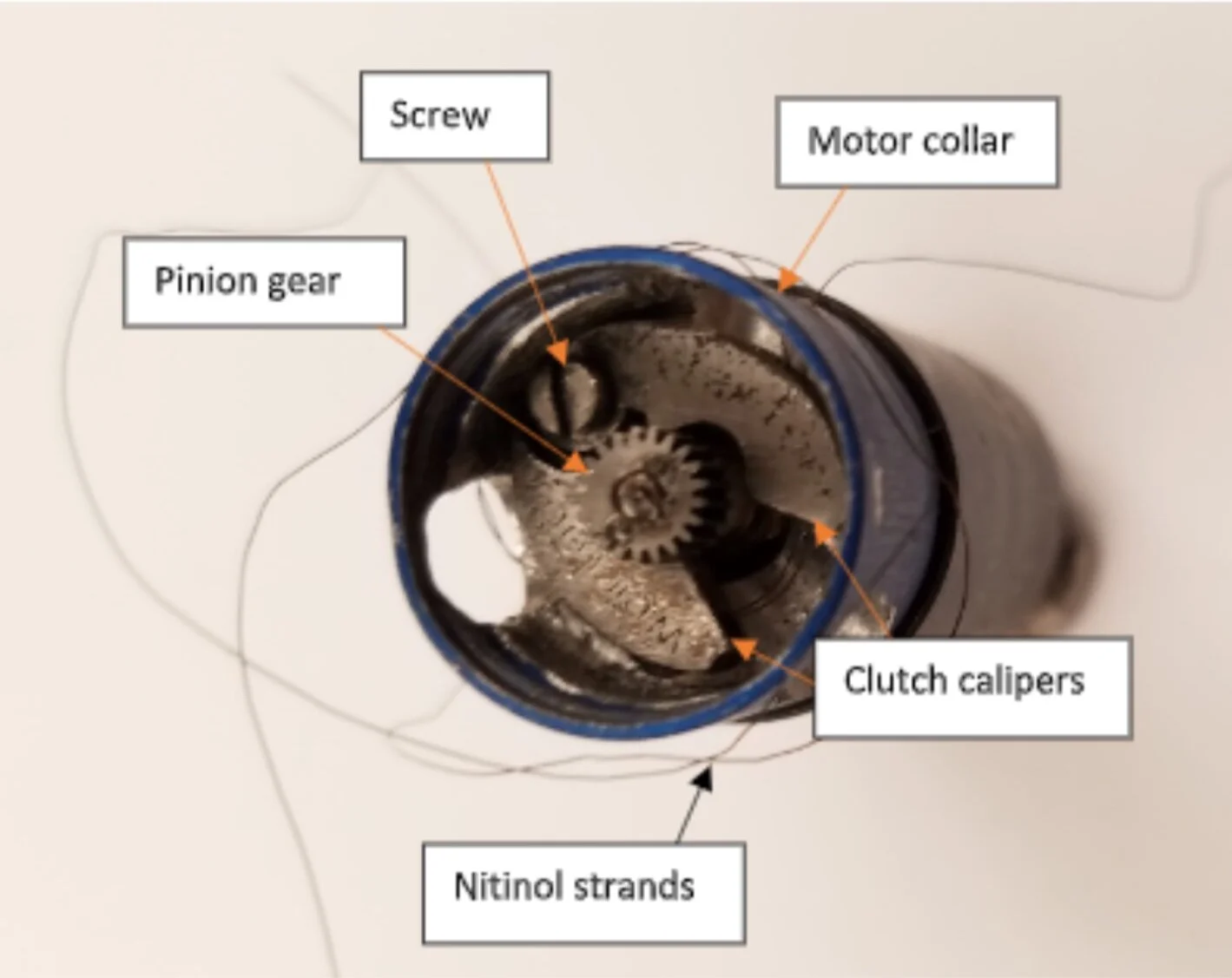

The standard motors that drive prosthetic fingers cannot provide both the speed and torque required to hold objects as efficiently as a human hand. This problem of high speed/torque can be solved by using multiple motors or transmissions to drive a prosthetic finger, but these increase weight, cost, and complexity of the prosthetic finger system, which lead to people abandoning their device. Presented here is a novel clutch mechanism that alleviates the high speed/torque problem by holding the motor in place during gripping using nickel-titanium “memory wire” called Flexinol. This clutch mechanism allows an inexpensive low-torque motor to drive fingers while retaining the grip strength benefits of a high torque motor thus reducing cost and weight of the prosthetic finger system.